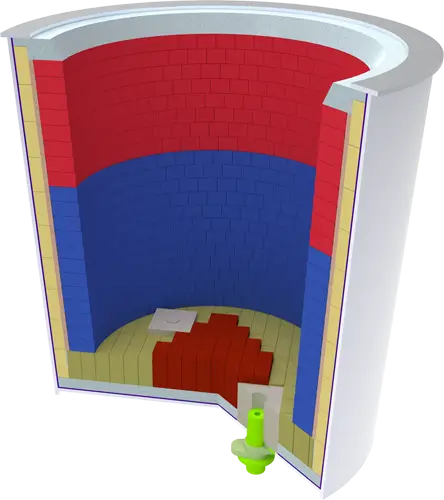

钢包的选型

根据冶炼条件,钢包有标准型和矮胖型两种包型可选。

1、传热计算

建立钢包数学模型,根据钢包结构特点,钢包传热计算做如下假设:

1)钢包壁视为无限长圆筒壁,钢包底和钢液表面视为无限大平壁;

2)按一维稳态热导率计算钢包壁、底部热导率。

3)忽略钢包各层耐火材料间及耐火材料与钢壳间的接触热阻;

4)钢包所用耐火材料物性参数不随温度变化;

5)热量仅沿着厚度方向从内向外传热,其他方向是均匀的。

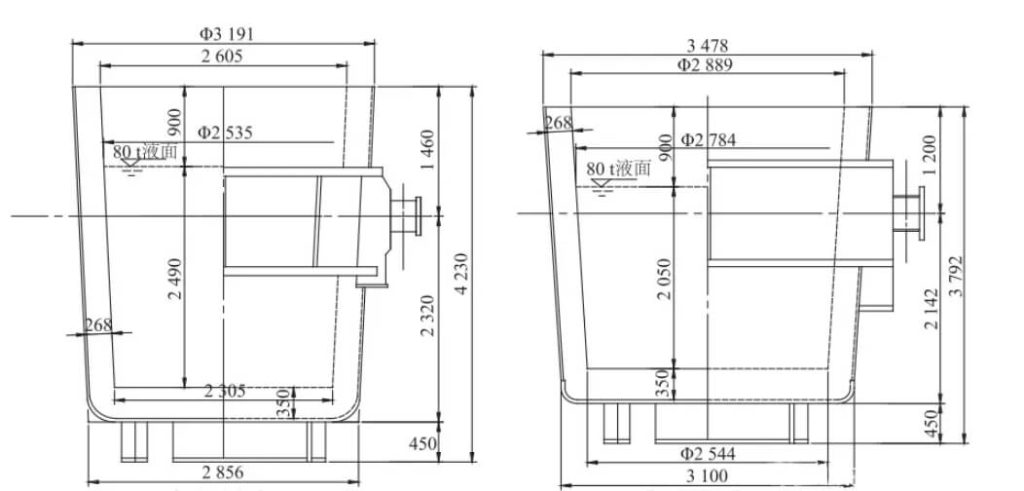

2、标准型钢包传热计算

钢包壁热传导铝镁尖晶石浇注料导热系数取0.7W/(m·K);λ钢壳为包壳的导热系数,Q345钢的导热系数48W/(m·K);d1为圆筒状钢包内钢水的直径,锥形钢包取上下面钢水直径的中间值,2418mm;d2为圆筒状钢包内耐材的直径,锥形钢包取耐材直径的中间值,2898mm;d3为圆筒状钢包内包南壳外径,锥形钢包取包壳外径的中间值,2948mm;l为圆筒状钢包钢水的高度,锥形钢包近似取钢水的高度,2490mm。

结果分析

1、传热的经济分析

经计算矮胖型钢包比标准型钢包要多散热12%。

而且随着品种结构的升级,大部分钢种需要经过精炼炉甚至VD炉或者RH真空精炼炉生产,钢包的在线使用时间明显增加,实际的能耗比理论值更大。

2、其它经济分析

钢结构投资矮胖型和标准型钢包的钢结构质量分别为19.8t和14.6t(见表3),按每座转炉配备10~12个钢包,钢结构按1万元/t计算,采用矮胖型钢包投资增加(52~62.4)万元。

3、冶金功能对比

钢包为炼钢生产重要设备之一。随着冶炼工艺的改进与发展,已经从早期的简单的冶金设备转变为重要的工艺设备,其中精炼过程需要在底部进行吹氩,从而促进夹杂物的上浮,均匀钢水成分,提高钢水纯净度等方面的作用。炉外二次精炼的作用在现代冶金的作用越发明显。据研究资料表明,气体流量一定时,熔池越深,气体具有的浮力势能越大,且气体上浮到钢渣界面因压力减小恒温膨胀做功增大,有利于提高气体的搅拌能力。

4、结论

(1)通过对两种钢包进行对比,标准型钢包在投资成本、运行成本等方面具有较大的优势。

(2)标准型钢包在能耗方面具有更大的优势,可以减少钢水温降、节约电耗。

(3)标准型钢包在冶金效果方面具有更大的优势,可以减少钢水的死区,除去夹杂物。

(4)标准型钢包可以减少涡流卷渣、提高钢水的纯净度。