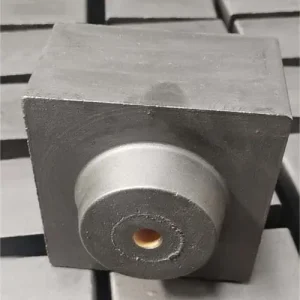

Tundish Nozzles Products Description :

Tundish Metering nozzles is a Refractories for Tundish and also a Tundish Nozzle Material for Tundish Nozzle Uses, are mainly with zirconium inserted, featuring high refractoriness, and low expansion rate, superior resistance to erosion/corrosion and thermal shock and long service life. According to customers’ different needs, changxing can provide the Tundish Nozzle Meter with various sizes and specifications.The steelmaking of tundish nozzle core,it’s a brick refracory material casting tundish nozzle and a high strength high toughness tundish nozzle. lt comes with a casting speed which stays controlled: it has the sequence time because of which it protects the clogging and eventually improves the productivity as well. As the compositions of it are made as per the industrial standard, it proves you with better Tundish Nozzles for life.

Tundish Nozzles Special Features:

Long casting sequence time.

Controlled casting speed.

Excellent resistance to oxidation.

Prevent clogging to improve productivity.

Special compositions of nozzles as per use in the industry.

Higher life of Nozzles.

Tundish Nozzles Performance Characteristics:

1.Standard Al-C body materails having high corrosion and thermal shock resistance.

2.Standard Al-C materails for the bowl structure having high corrosion resistance.

3.Standard anti-blocking materails can prevent Al2O3 adhesion inside the nozzle.

4.Standard argon injection to prevent air suction.

5.High-wearing resistance and accurate dimensions used in the bottom materails insure taphole to achieve a quick change.

Reviews

There are no reviews yet.