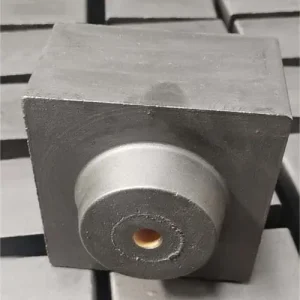

Tundish Impact Plate Advantages:

The impact plate is used for liquid steel induction area of tundish, and the nozzle well block is used to install the nozzle, its mark, material quality and physical chemical indexes are similar to the slag dam. Users can make rational combination to the slag dam, impact plate and nozzle well block based on the smelting conditions and service conditions of tundish. We manufacture products such as tundish box and tundish impact plate that are used in the initial point that molten steel from the ladle and tundish surface meet. Impact plate can effectively ensure the safety of tundish and improve its service life.The impact plate products developed by our company have the characteristics of high thermal strength and long service life.This series of products are mainly divided into magnesium aluminum spinel and magnesium series, which can be reasonably matched according to customers’ different requirements such as smelting process, service time .

Tundish Impact Plate Application:

The tundish, as the last refractory-lined reactor, gives enough space to remove inclusions by optimizing the flow of steel. The basic component of the tundish is the impact pad, the shape of which creates a suitable flow of steel, thus making it part of the tundish metallurgy. The optimal steel flow in the tundish must avoid creating dead zone areas, or the slag “eye” phenomenon in the slag layer around the ladle shroud and is intended to create conditions for the release of inclusions by promoting reactions at the steel-slag phase interface. The flow also has to prevent excessive erosion of the tundish refractory lining. The impact pad has a wavy upper surface which significantly reduces the horizontal surface area in the region of impact where molten iron or steel enters the tundish vessel. This wavy surface substantially reduces the vertical splashing of molten iron or steel entering the vessel, causing a significant reduction in agitation and turbulence within the vessel. The impact plate may exist as a discrete structure or may form an integral part of the structure of the tundish vessel.

Reviews

There are no reviews yet.