Tundish Coating Description:

Tundish Coating is a necessary material for replacing the thermal shield and realizing continuous casting. It has features such as easy smearing, anti-cracking, erosion resistance and easy disintegration. The raw material of magnesia calcia tundish coating mixture is composed of dolomite or sintered magnesite calcia, sintered or fused magnesite, binder, additives(dispersant, plasticizer, sintering agent) and organic fibers. Dolomite is compound salt which is consisted of CaCO3 and MgO3, its theoretical CaO content is 30.4%, MgO content is 21.9%. Calcined dolomite contains 58% CaO and 42% MgO. But dolomite clinker is easy to be hydrated, it is difficult to be used for preparing coating mixture, so usually adopts dolomite sand and sintered( fused) magnesite or anti-hydration magnesia calcia sand and sintered magnesite for the making of tundish coating mixture.

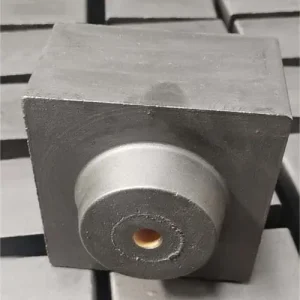

Tundish Coating Advantages:

Tundish coating has high refractoriness, good construction performance, no cracks and no pollution to molten steel.

Tundish Coating Features

- High spread-ability

- High Melting Point

- Low thermal conductivity

Reviews

There are no reviews yet.