Submerged Entry Nozzle Features:

· Ultimate production and conformity quality

· Special designs for quick change systems and thin slab casters

· Monolythic pressing of the different materials for a homogeneous structure

· High erosion resistant zirconia materials in the slag zone for long casting times

· Different methods and materials against Alumina clogging

· Submerged Entry Nozzles for the usage without preheating (Cold-Start SEN)

Submerged Entry Nozzle Characteristics:

1.Good sealing: It has a good fit with our plug products, and the sealing performance is good after the stopper and the nozzle are

closed.

2.Anti-erosion: Advanced material formulation to effectively resist the physicochemical effects of the melt.

3.Antioxidant: Advanced anti-oxidation mechanism to ensure good protection of graphite in products.

4.High temperature resistance:1770 °C – 2000 °C

5.High strength: high-quality materials, high-pressure pressing, reasonable combination, high temperature strength, scientific

product design, high anti-scour ability.

6.Long service life: could use more heats by a long working life

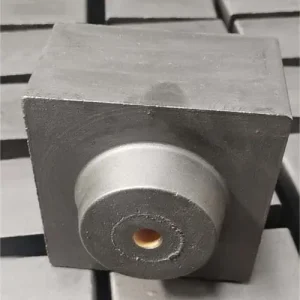

Submerged entry nozzle for introducing molten steel into a casting mold comprising:

1. nozzle structure defining a central bore and two transverse exit ports communicating with the bottom of said central bore;

2.said central bore terminating at an upwardly dish-shaped bottom surface that extends to the periphery of said nozzle structure and forms the lower surface regions of said exit ports, whereby molten steel flowing across said’upwardly dish-shaped bottom surface is directed outwardly and upwardly from said nozzle structure.

Reviews

There are no reviews yet.