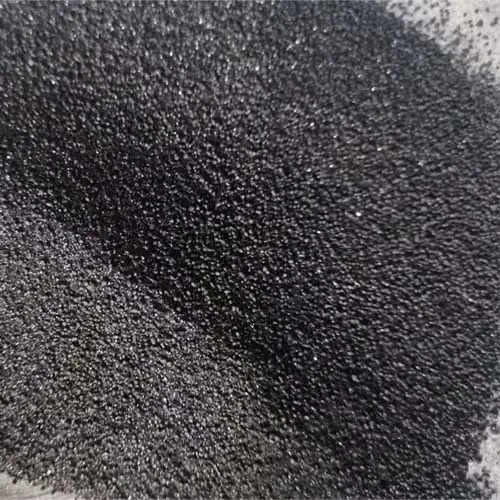

Ladle Filling Sand Application

High refractoriness and heat resistance to a temperature of up to or greater than 1700C. Excellent physical and chemical resistance and not affect analysis and fusion compounds during melting operations.

How is ladle filler sand used in foundries for pouring metal?

A ladle is used in the foundries to receive molten metal or steel and to move it between furnace and where it is to be casted into a mould. The metal is at extremely high temperatures and is liquid. At the opening of the slide gate, the majority of the casting ladle sand will flow out from both the nozzle and the area around the gate, while the ferrostatic pressure in the ladle which is being exerted by the steel will cause the sintered layer to break, thereby releasing the molten metal.

Reviews

There are no reviews yet.